What can we do for you?

FIEM SNC has been dealing with industrial automation for more than thirty years, exploiting the use of the best technologies, to bring its services all over the world. Our team of professionals differentiates the vision of the work based on the needs of our customers, in order to ensure each of the specific and exclusive processes.

- Vision Work

- Custom quotes

- Order materials

- Machine board

- Experimentation

- Verifications

- Electrical design

- Electrical scheme

- Panel wiring

- Safety

- Testing at the customers’ premises

- Supervision

- Progettazione HW e SW

- PLC CNC HMI DRIVE

- Impianti automatizzati

- Rilascio certificazioni UNI EN e UC CSA

- Manutenzione ordinaria e straordinaria

Ideation, realization and maintenance

Discover our services

Electrical Systems

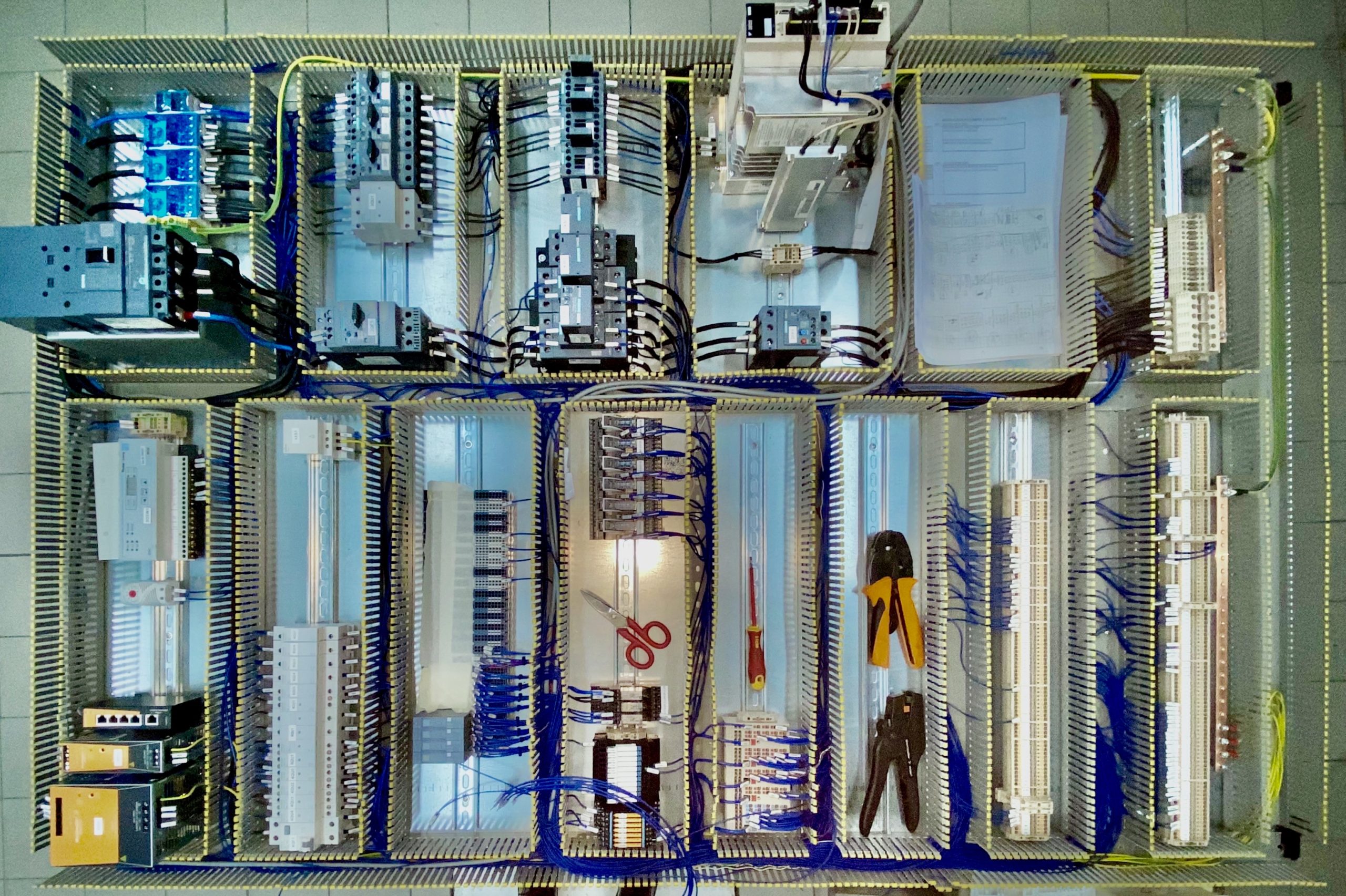

FIEM SNC carries out the design, construction and installation of electrical systems and home automation systems both for homes and for different work environments, with qualified interventions and in accordance with the law. Thanks to the collaboration with professionals and companies specialized in the on-board electrical plant engineering sector, we are able to offer the following services: design of the schemes and construction of electrical systems on the machine from scratch or adaptation of the existing one; all this by verifying the conformity of the existing systems, in compliance with the specifications indicated in the reference standard (CEI EN 60204) and the validation of the safety functions pursuant to UNI EN ISO 13849-1 and UNI EN ISO 13849-2.

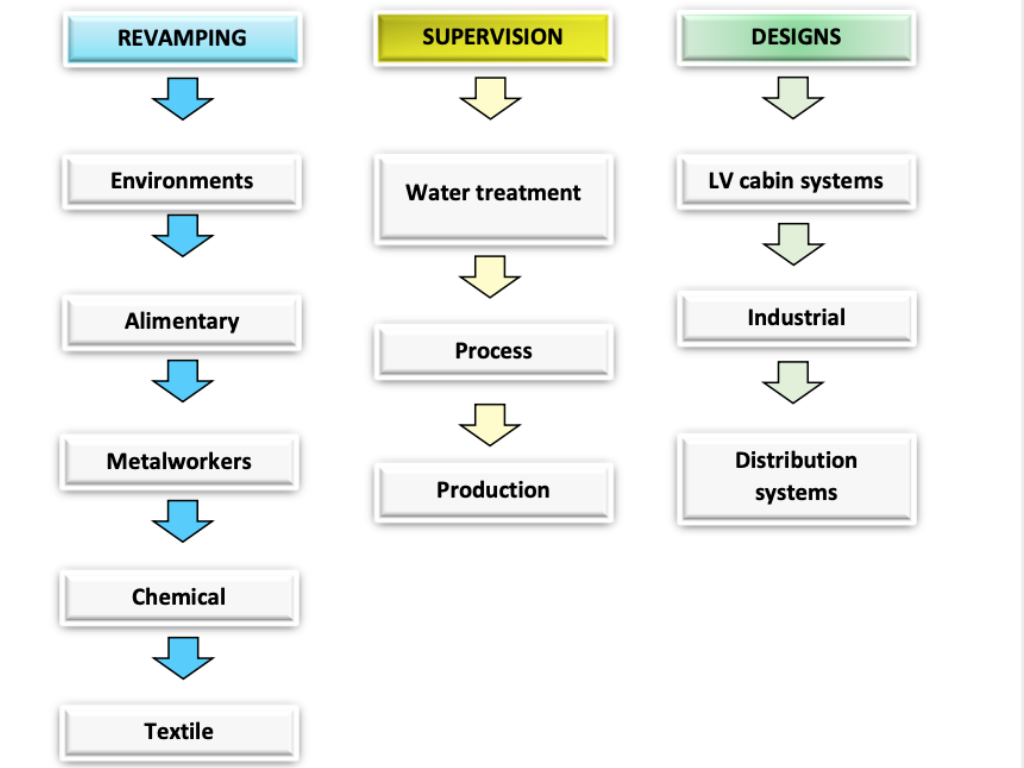

Design

FIEM SNC in Buttigliera d’Asti has been a company specialized for years in the industrial automation sector, in the design of systems, in the design and construction of machinery, Low Voltage substations, industrial systems and automated distribution systems for companies, in programming PLC, Siemens CNC, Rockwell and Omron Softwares. It makes use of the best collaborators in the area, to extend its skills all over the world.

Grindings Machines

Our team of professionals specializes in professional technical assistance for the repair, modernization and overhaul of Cincinnati Centerless Grinding Machines. When we talk about grinding machines, we mean all the processes and changes made on a machine, in order to improve its yield and to guarantee end customers, all over the world, an innovative and very precise product.

Retrofitting

FIEM SNC specializes in the Retrofitting of thrufeed, infeed and ball grinding machines, bringing new technologies and high machining precision to machines whose mechanics are stable and tested. It is a mechanism that allows modern machinery to be obtained from obsolete systems, capable of competing in productivity and precision with those of the new generation. Using the most advanced technologies, the theme of FIEM SNC prepares a system that allows the customer to manage the line in a simple and immediate way.

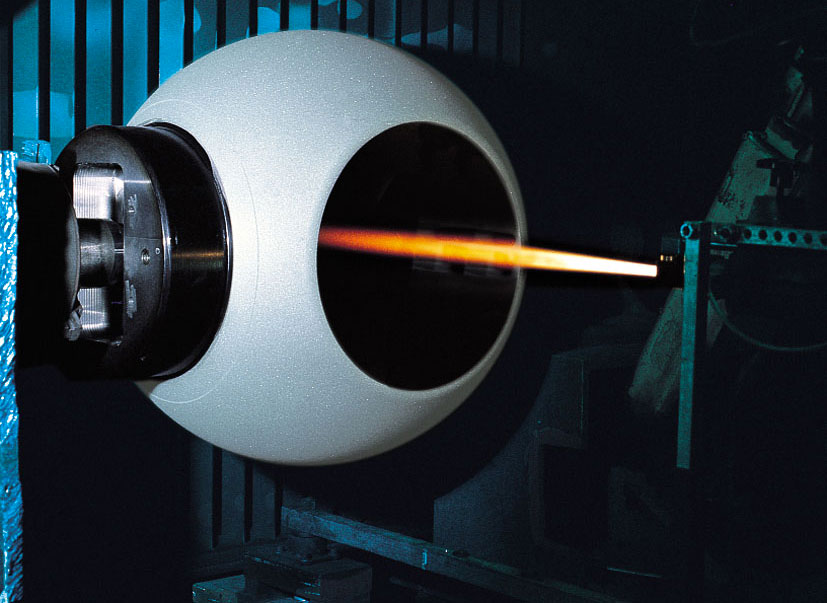

Coating

FIEM SNC designs and manufactures the electrical, software and fluidic part of spraying systems such as HVOF, APS plasma and Cascade technology plasma, in collaboration with the company Flame Spray, specialized in Thermal Spray coatings and processes since 1969. All Thermal Spray processes they are based on the same principle: plasticize a material, in the form of wire or powder, and accelerate it against the substrate to be coated. The elasticized particles will impact the substrate, deforming and then solidifying immediately. The coating is formed when millions of particles are deposited on each other. These coatings are anchored to the substrate mechanically or, through subsequent thematic treatments, metallurgically.

Wheels Production Lines

For more than ten years, FIEM SNC has been generating in Retrofitting and/or designing, in collaboration with numerous mechanical companies such as ESAM Italy, new lines for the forming of Wheels (rim) for machines, tractors, trucks, for manufacturing companies all over the world, including China, India., Turkey, Belarus, England, America etc… These machines for the production of iron wheels are used in the automotive, truck and agricultural sectors. When we talk about this specialty, we refer properly to forming, welding, Rolling, calibration and dimensional control of the equipment, in order to ensure our customers the best usable product. It is a precise, fast and highly technological production process. The latest lines produced by FIEM SNC have become, in the world of wheels, the most efficient, fast and precise production lines and boast a complete type change of only 20 minutes.

Maintenance

Among the technical-professional requirements of FIEM SNC we mention the part relating to the maintenance of the systems. In fact, in addition to the design, construction and installation of the machinery, the company takes care of their ordinary and extraordinary maintenance. Our team of professionals offers interventions aimed at limiting normal degradation of use as well as dealing with accidental events, which entail the need for first interventions, without however modifying the structure of the plant on which the intervention is carried out or its intended use.

Certifications

It is of fundamental importance for a company to obtain all the conformity certifications according to the safety requirements. One of FIEM SNC’s services is precisely to evaluate the structures and products of its customers, to then issue these certifications. Hence a particular attention to electrical panels and related wiring. The machines destined for the USA, in fact, must comply with the requirements laid down by the American UL 508-A standard which indicates the safety standards relating to the construction of the electrical panels intended for the American market. To reach the Canadian market, however, the CSA certification of the products is guided by the CSA 22-2 N°14 regulation. FIEM SNC is part of the companies recognized to guarantee compliance with the minimum safety standards and requirements envisaged by these countries.

Software e Hardware

FIEM SNC has a team specialized in Hardware and Software design. The field involves numerous areas, specifically touching also the development of hardware and software for highly technological production lines, also asserved by robots. The technician designs the electromechanical apparatus, or the command and control system, according to the definition of the technical specifications and the processing cycle. Subsequently he takes care of the software programming for PLC, checking its functionality during accurate simulations. It then assembles the electrical panels and sizes the PLC devices with the relative wiring. Lastly, using the construction drawings to install the automation on the machines, it starts up and tests the system; then taking care of both ordinary and extraordinary maintenance of the device.

Our Projects

Recent Projects

Coating Systems

FIEM SNC designs and manufactures the electrical, software and fluid parts of spraying systems such as

- HVOF

- PLASMA APS

- PLASMA CASCADE

in collaboration with the FLAME SPRAY company, specialized in Thermal Spray coatings and processes since 1969.

Abrasive paper treatment

FIEM SNC in collaboration with the company O.R.B. in Alba has been involved in the construction of machinery for the treatment of abrasive paper.

Customized systems according to specific indications starting from the design, up to the final installation at SAIT, client company, producer of abrasive paper.