Project

Transport Upgrade of Elmotec Rewinding Lines

Elmotec

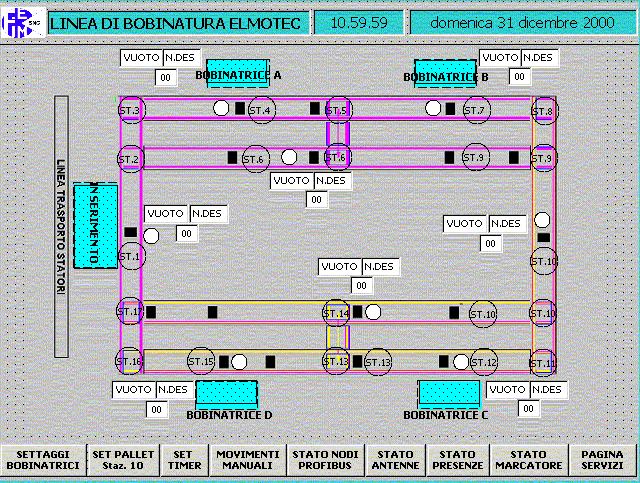

One case brought to the attention of FIEM SNC in 2000 was the installation of the ELMOTEC winding lines. Being a completely closed system, there was no possibility to perform any search with a programming suitcase, since the automation depended solely on a PC (PILZ) to which all the Input/ Output, the RFID identification systems belonged (pallet coding) through an Interbus network. In the event of a failure, maintenance would have had very few options to find the problem. FIEM SNC, using the most advanced technologies of the time, has solved these problems by designing a system that would replace the control PC with an S7-300 PLC, a Touch screen panel, ET200X I / O cards and RFID MOBY system, changing the INTERBUS network with a PRIFIBUS DP network. This system allowed the customer to manage the line in a simple and immediate way, becoming a result of historical importance for FIEM SNC itself.

Coating Systems

Coating

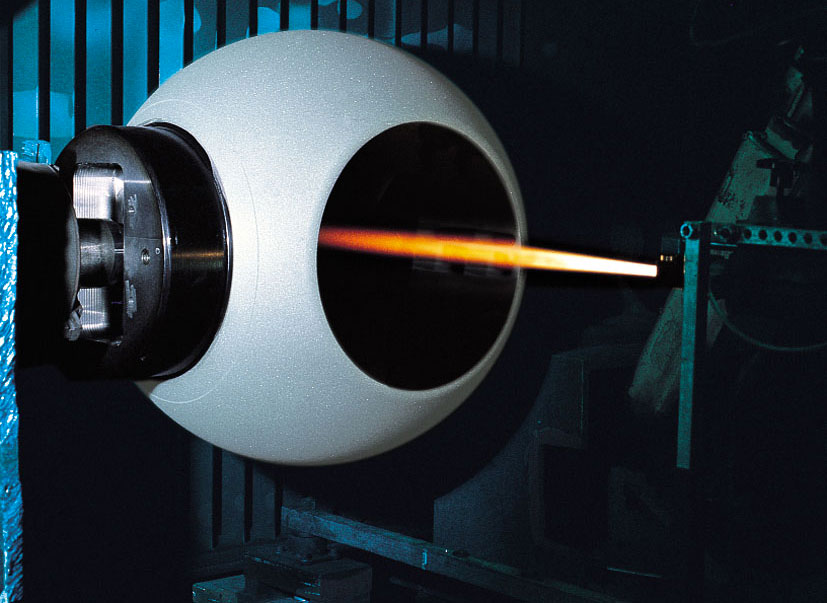

FIEM SNC designs and manufactures the electrical, software and fluidic part of spraying systems such as HVOF, APS plasma and Cascade technology plasma, in collaboration with the company Flame Spray, specialized in Thermal Spray coatings and processes since 1969. All Thermal Spray processes they are based on the same principle: plasticize a material, in the form of wire or powder, and accelerate it against the substrate to be coated. The elasticized particles will impact the substrate, deforming and then solidifying immediately. The coating is formed when millions of particles are deposited on each other. These coatings are anchored to the substrate mechanically or, through subsequent thematic treatments, metallurgically.

Repair, modernize or review the grinding machines.

Grinding Machines

Over the years, FIEM SNC has acquired an excellent knowledge of Cincinnati past and plunge adjustments. In cooperation with the company Flame Spray, given the efficiency and stability of the base casting, FIEM revamps these machines, mounting the new control technologies on a tested and stable base, in order to guarantee final customers, in all the world, an innovative and very precise product (stability above one micron).

Machines for the production of iron wheels

Wheels Production Lines

For more than ten years, FIEM SNC has been generating in Retrofitting and/or designing, in collaboration with numerous mechanical companies such as ESAM Italy, new lines for the forming of Wheels (rim) for machines, tractors, trucks, for manufacturing companies all over the world, including China, India., Turkey, Belarus, England, America etc… These machines for the production of iron wheels are used in the automotive, truck and agricultural sectors. When we talk about this specialty, we refer properly to forming, welding, Rolling, calibration and dimensional control of the equipment, in order to ensure our customers the best usable product. It is a precise, fast and highly technological production process. The latest lines produced by FIEM SNC have become, in the world of wheels, the most efficient, fastest and most precise production line and show a complete type change of just 20 minutes.

Design

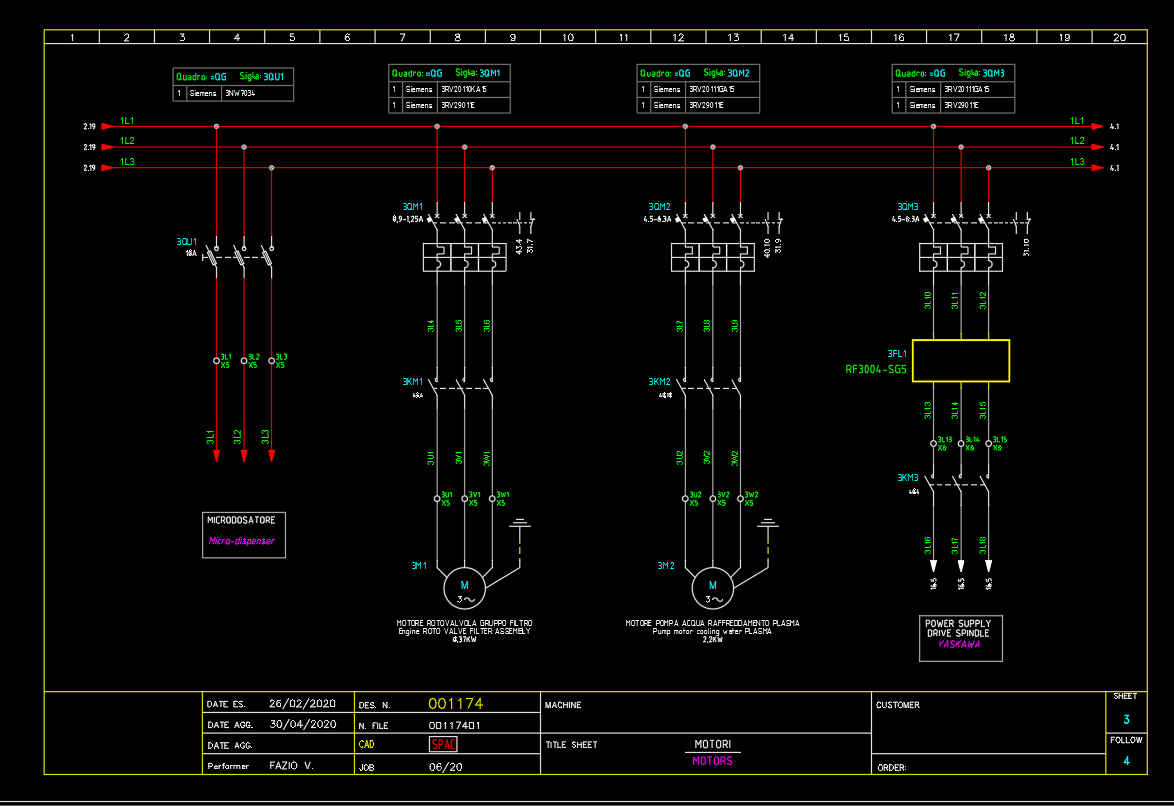

Hardware design with, Spac 2023. Supervision software design on PC (SCADA), network data transfer, data analysis and acquisition, trends, reports, wiring of electrical panels of machines and systems and software development with PLC.